Fastenal Company Reports 2022 Third Quarter Earnings

Fastenal Company (Nasdaq:FAST), a leader in the wholesale distribution of industrial and construction supplies, today announced its financial results for the quarter ended September 30, 2022. Except for share and per share information, or as otherwise noted below, dollar amounts are stated in millions. Throughout this document, percentage and dollar calculations, which are based on non-rounded dollar values, may not be able to be recalculated using the dollar values included in this document due to the rounding of those dollar values. References to daily sales rate (DSR) change may reflect either growth (positive) or contraction (negative) for the applicable period.

Performance Summary

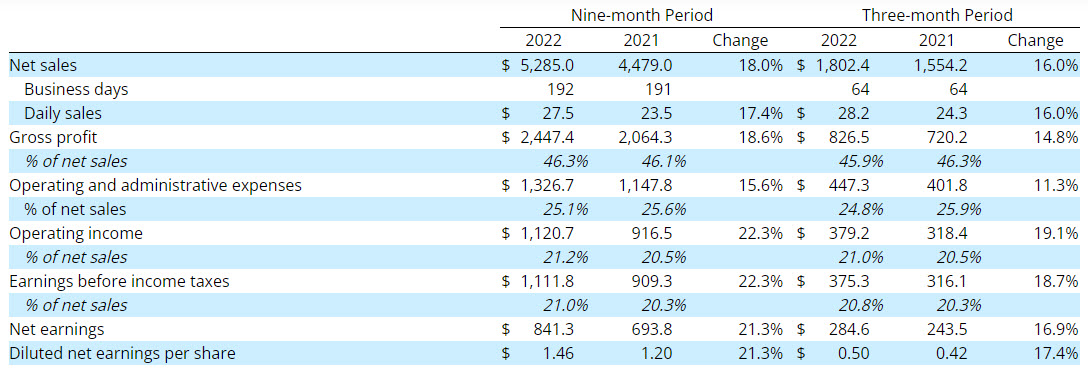

Quarterly Results of Operations

Net sales increased $248.2, or 16.0%, in the third quarter of 2022 when compared to the third quarter of 2021. The number of business days were the same in both periods. We estimate adverse weather that impacted the southeastern U.S. reduced our quarterly growth by 10 to 30 basis points. We experienced higher unit sales in the third quarter of 2022 that contributed to the increase in net sales in the period. This was due to good underlying demand in markets tied to industrial capital goods and commodities, which more than offset softer markets tied to consumer goods and relatively lower growth in construction. Foreign exchange negatively affected sales in the third quarter of 2022 by approximately 60 basis points.

The overall impact of product pricing on net sales in the third quarter of 2022 was 550 to 580 basis points compared to the third quarter of 2021. The increase is from actions taken over the past twelve months intended to mitigate the impact of marketplace inflation for our products, particularly fasteners, and transportation services. We did not take any broad pricing actions in the third quarter of 2022, and price levels in the market remained stable. The favorable impact of product pricing moderated in the third quarter of 2022 relative to the second quarter of 2022 due to comparisons against initial price events that began in the third quarter of 2021. Spot prices in the marketplace for many inputs, particularly fuel, transportation services, and steel, began to decline during the period. Due to our long supply chain for fasteners and certain non-fastener products, however, it is likely to take several quarters before this is reflected in our cost of goods. The impact of product pricing on net sales in the third quarter of 2021 was 230 to 260 basis points.

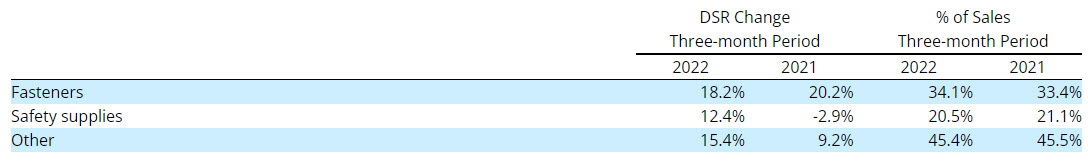

From a product standpoint, we have three categories: fasteners, safety supplies, and other product lines, the latter of which includes eight smaller product categories, such as tools, janitorial supplies, and cutting tools. The DSR change when compared to the same period in the prior year and the percent of sales in the period were as follows:

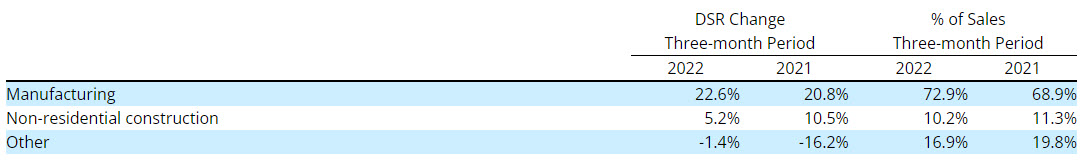

Our end markets consist of manufacturing, non-residential construction, and other, the latter of which includes resellers, government/education, and transportation/warehousing. The DSR change when compared to the same period in the prior year and the percent of sales in the period were as follows:

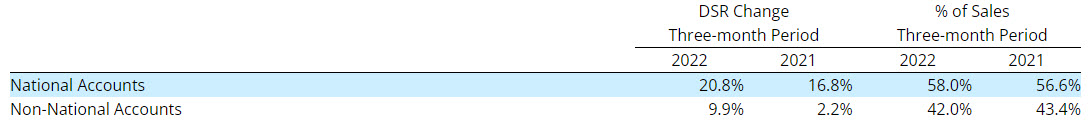

We report our customers in two categories: national accounts, which are customers with a multi-site contract, and non-national accounts, which include large regional customers, small local customers, and government customers. Sales to most of our national account customers grew in the third quarter of 2022 over the year earlier period, as our sales grew at 83 of our Top 100 national account customers. The DSR change when compared to the same period in the prior year and the percent of sales in the period were as follows:

Our gross profit, as a percentage of net sales, declined to 45.9% in the third quarter of 2022 from 46.3% in the third quarter of 2021. The decline in our gross profit percentage was primarily related to three factors. First, the net impact from product and customer mix was dilutive, reflecting relatively strong growth of our Onsite and national account customers, which tend to be larger and have a lower gross margin percentage. Second, we experienced unfavorable price/cost, reflecting stable pricing for our products and services but slightly higher costs. Third, we had a $3.4 write down in the value of certain gloves in our inventory. Demand for nitrile gloves expanded dramatically during the pandemic, and we purchased significant quantities in 2021 to address needs from certain industries. As market conditions normalized, some of the product had an inventory value above current market value, a situation we did not see reversing. These impacts were partly offset by strong freight revenue, which narrowed our freight losses, and our ability to leverage organizational expenses.

Our operating income, as a percentage of net sales, increased to 21.0% in the third quarter of 2022 from 20.5% in the third quarter of 2021. The increase in our operating income percentage was driven by improved operating expense leverage, which more than offset the decline in our gross profit percentage. Our operating and administrative expenses, as a percentage of net sales, fell to 24.8% in the third quarter of 2022 from 25.9% in the third quarter of 2021. This was primarily due to a decline, as a percentage of net sales, in occupancy-related and employee-related expenses.

Employee-related expenses, which represent 70% to 75% of total operating and administrative expenses, increased 14.1% in the third quarter of 2022 compared to the third quarter of 2021. We experienced an increase in employee base pay, albeit at a rate below the growth in sales, due to higher average FTE during the period and, to a lesser degree, higher average wages. Bonus and commission payments increased at a rate greater than sales, reflecting improved business activity and financial performance versus the year-ago period. We also had higher profit sharing expense. These costs were partly offset by lower healthcare expenses reflecting post-COVID normalization of the healthcare environment. Occupancy-related expenses, which represent 15% to 20% of total operating and administrative expenses, increased 3.8% in the third quarter of 2022 compared to the third quarter of 2021. Costs increased related to investment in hardware and equipment, including Fastenal Managed Inventory (FMI) devices and materials and equipment involved in maintaining and upgrading our branches and hubs. Total building costs were mostly flat in the period. Combined, all other operating and administrative expenses, which represent 10% to 15% of total operating and administrative expenses, increased 5.9% in the third quarter of 2022 compared to the third quarter of 2021. The increase in other operating and administrative expenses relates primarily to higher product movement and fuel costs for our local truck fleet, increased spending on information technology services, and increased spending for travel and supplies. This was only partly offset by reduced spending for general insurance.

Our net interest expense was $3.9 in the third quarter of 2022, compared to $2.3 in the third quarter of 2021. This increase was due to higher average debt balances and higher average interest rates during the period.

We recorded income tax expense of $90.7 in the third quarter of 2022, or 24.2% of earnings before income taxes. Income tax expense was $72.6 in the third quarter of 2021, or 23.0% of earnings before income taxes. We believe our ongoing tax rate, absent any discrete tax items or broader changes to tax law, will be approximately 24.5%.

Our net earnings during the third quarter of 2022 were $284.6, an increase of 16.9% compared to the third quarter of 2021. Our diluted net earnings per share were $0.50 during the third quarter of 2022, which increased from $0.42 during the third quarter of 2021.

Growth Driver Performance

- We signed 86 new Onsite locations (defined as dedicated sales and service provided from within, or in close proximity to, the customer’s facility) in the third quarter of 2022, resulting in year-to-date signings of new Onsite locations of 294. We had 1,567 active sites on September 30, 2022, which represented an increase of 14.6% from September 30, 2021. Daily sales through our Onsite locations, excluding sales transferred from branches to new Onsites, grew at a greater than 20% rate in the third quarter of 2022 over the third quarter of 2021. This growth is due to improved business activity from our Onsite customers and, to a lesser degree, contributions from the increase in the number of Onsites we operate. We continue to anticipate signing 375 to 400 Onsites in 2022, though we currently expect to be in the lower half of this range given year-to-date signings.

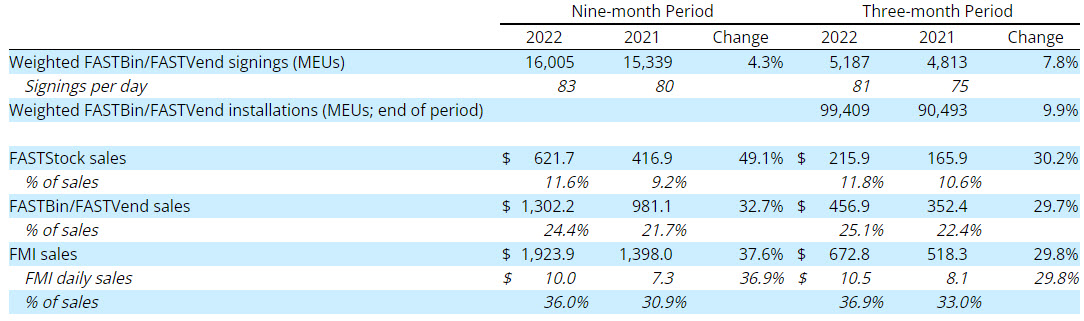

- FMI Technology is comprised of our FASTStock? (scanned stocking locations), FASTBin® (infrared, RFID, and scaled bins), and FASTVend® (vending devices) offering. FASTStock’s fulfillment processing technology is not embedded, is relatively less expensive and highly flexible in application, and delivered using our proprietary mobility technology. FASTBin and FASTVend incorporate highly efficient and powerful embedded data tracking and fulfillment processing technologies. Prior to 2021, we reported exclusively on the signings, installations, and sales of FASTVend. Beginning in the first quarter of 2021, we began disclosing certain statistics around our FMI offering. The first statistic is a weighted FMI® measure which combines the signings and installations of FASTBin and FASTVend in a standardized machine equivalent unit (MEU) based on the expected output of each type of device. We do not include FASTStock in this measurement because scanned stocking locations can take many forms, such as bins, shelves, cabinets, pallets, etc., that cannot be converted into a standardized MEU. The second statistic is revenue through FMI Technology which combines the sales through FASTStock, FASTBin, and FASTVend. A portion of the growth in sales experienced by FMI, particularly FASTStock and FASTBin, reflects the migration of products from less efficient non-digital stocking locations to more efficient, digital stocking locations.

The table below summarizes the signings and installations of, and sales through, our FMI devices.

We continue to anticipate weighted FASTBin and FASTVend device signings in 2022 in a range of 21,000 to 23,000 MEUs.

All metrics provided above exclude approximately 7,500 non-weighted vending devices that are part of a leased locker program.

- Our eCommerce business includes sales made through an electronic data interface (EDI), or other types of technical integrations, and through our web verticals. Daily sales through eCommerce grew 50.2% in the third quarter of 2022 and represented 18.0% of our total revenues in the period.

Our digital products and services are comprised of sales through FMI (FASTStock, FASTBin, and FASTVend) plus that proportion of our eCommerce sales that do not represent billings of FMI services (collectively, our Digital Footprint). We believe the data that is created through our digital capabilities enhances product visibility, traceability, and control that reduces risk in operations and creates ordering and fulfillment efficiencies for both ourselves and our customers. As a result, we believe our opportunity to grow our business will be enhanced through the continued development and expansion of our digital capabilities.

Our Digital Footprint in the third quarter of 2022 represented 49.5% of our sales, an increase from 43.7% of sales in the third quarter of 2021.

Balance Sheet and Cash Flow

We produced operating cash flow of $257.9 in the third quarter of 2022, an increase of 54.1% from the third quarter of 2021, representing 90.6% of the period’s net earnings versus 68.8% in the third quarter of 2021. While the conversion rate in the third quarter of 2022 remains below historical norms for the period, it also represents the first year-over-year improvement in the metric since the first quarter of 2021. The resources required for operating working capital eased relative to prior periods.

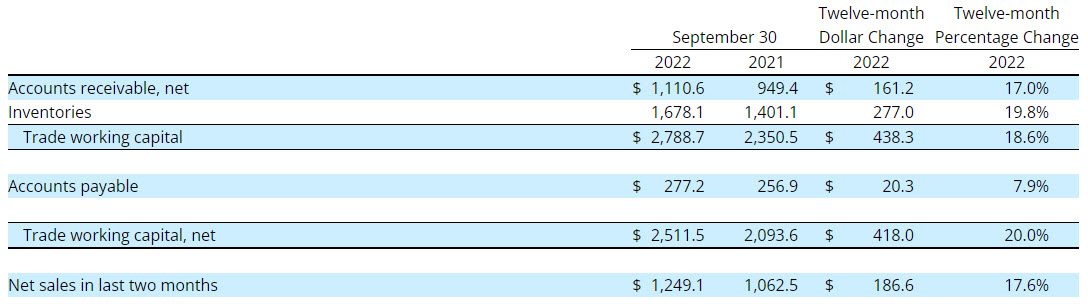

The dollar and percentage change in accounts receivable, net, inventories, and accounts payable as of September 30, 2022 when compared to September 30, 2021 were as follows:

Note – Amounts may not foot due to rounding difference.

The increase in our accounts receivable balance in the third quarter of 2022 is primarily attributable to two factors. First, our receivables increased as a result of improved business activity and resulting growth in our customers’ sales. Second, we continue to experience a shift in our mix due to relatively stronger growth from national account customers, which tend to be larger and carry longer payment terms than our non-national account customers.

The increase in our inventory balance in the third quarter of 2022 is primarily attributable to three factors. First, our inventory increased to support improved business activity by our customers. Second, over the past twelve months we have aggressively imported product to deepen our inventory as a means of addressing supply disruptions and provide our customers with resilient and robust product availability. In the third quarter of 2022, we achieved target product availability in our hubs and experienced easing constraints in our supply chain, which allowed us to slightly shorten our product ordering cycle. Third, inflation was responsible for slightly less than half of the overall increase. The impact of inflation remains significant but continues to moderate, with the third quarter being the first quarter in 2022 where inflation was not the primary driver of inventory growth in the period.

Our accounts payable balance increased due to higher product purchases to support the growth of our customers and, to a lesser degree, the favorable impact of timing on certain payable balances.

During the third quarter of 2022, our investment in property and equipment, net of proceeds from sales, was $44.4, which is a decrease of 2.4% from the third quarter of 2021. We had higher spending for FMI equipment, information technology, and hub safety and automation upgrades, which was more than offset by lower spending on a new building in downtown Winona, completed in 2021.During the first nine months of 2022, our investment in property and equipment, net of proceeds from sales, was $120.9, which is an increase of 13.0% from the first nine months of 2021. The most significant areas driving this increase are higher spending on hub safety and automation upgrades, FMI equipment, and information technology, only partly offset by lower spending on a new building in downtown Winona, completed in 2021.We now expect our investment in property and equipment, net of proceeds of sales, to be within a range of $170.0 to $190.0 (versus our prior $180.0 to $200.0), an increase from $148.2 in 2021. This annual increase reflects primarily: (1) higher spending on FMI equipment in anticipation of higher signings, a deepening of FMI unit inventory to address supply chain risks, and higher unit costs; (2) an increase in spending on hub properties to reflect upgrades to and investments in automation, as well as facility upgrades; and (3) an increase in manufacturing capacity to support demand and expand capabilities. We reduced our range for the full year of 2022 due to slightly lower purchases of FMI devices deriving from our lower signings activity, slightly lower vehicle purchases due to availability constraints, and higher asset sales.

During the third quarter of 2022, we returned $272.8 to our shareholders in the form of dividends ($177.5) and purchases of our common stock ($95.3), compared to $161.0 in the third quarter of 2021, all in the form of dividends. During the first nine months of 2022, we returned $679.0 to our shareholders in the form of dividends ($534.4) and purchases of our common stock ($144.6), compared to $482.6 in the first nine months of 2021, all in the form of dividends.

Total debt on our balance sheet was $555.0 at the end of the third quarter of 2022, or 14.9% of total capital (the sum of stockholders’ equity and total debt). This compares to $365.0, or 11.0% of total capital, at the end of the third quarter of 2021.

Additional Information

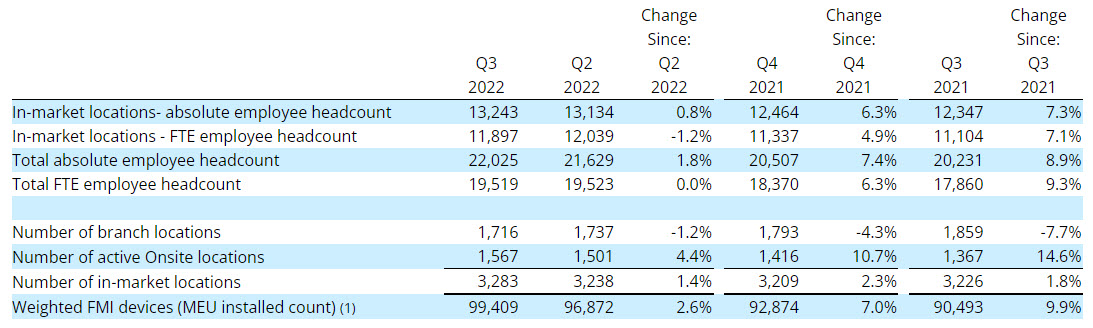

The table below summarizes our total and FTE (based on 40 hours per week) employee headcount, our investments related to in-market locations (defined as the sum of the total number of branch locations and the total number of active Onsite locations), and weighted FMI devices at the end of the periods presented and the percentage change compared to the end of the prior periods.

(1) This number excludes approximately 7,500 non-weighted devices that are part of our locker lease program.

During the last twelve months, we increased our total FTE employee headcount by 1,659. This reflects an increase in our in-market and non-in-market selling FTE employee headcount of 1,131 to support growth in the marketplace and sales initiatives targeting customer acquisition. We had an increase in our distribution center FTE employee headcount of 329 to support increasing product throughput at our facilities and to expand our local inventory fulfillment terminals (LIFTs). We had an increase in our remaining FTE employee headcount of 199 that relates primarily to personnel investments in information technology, manufacturing, and operational support, such as purchasing and product development.

We opened three branches in the third quarter of 2022 and closed 24 branches, net of conversions. We activated 92 Onsite locations in the third quarter of 2022 and closed 26, net of conversions. In any period, the number of closings tends to reflect both normal churn in our business, whether due to redefining or exiting customer relationships, the shutting or relocation of customer facilities that host our locations, or a customer decision, as well as our ongoing review of underperforming locations. Our in-market network forms the foundation of our business strategy, and we will continue to open or close locations as is deemed necessary to sustain and improve our network, support our growth drivers, and manage our operating expenses.

For the complete press release, click here.

Contact:

Taylor Ranta Oborski – Financial Reporting & Regulatory Compliance Manager – (507) 313-7959

Source: Fastenal Company